I spent my life working in factories. At first, I supported production in various roles, but eventually I found my home in Information Technology. Over the course of my career, I learned an astounding number of new concepts and skills while also developing a deep respect for engineers. I met people who invented things and others who figured out how to make them. My sense of wonder, especially in my younger years, was often tangled up with feelings of inadequacy. I simply didn’t measure up.

That changed when I discovered W. Edwards Deming.

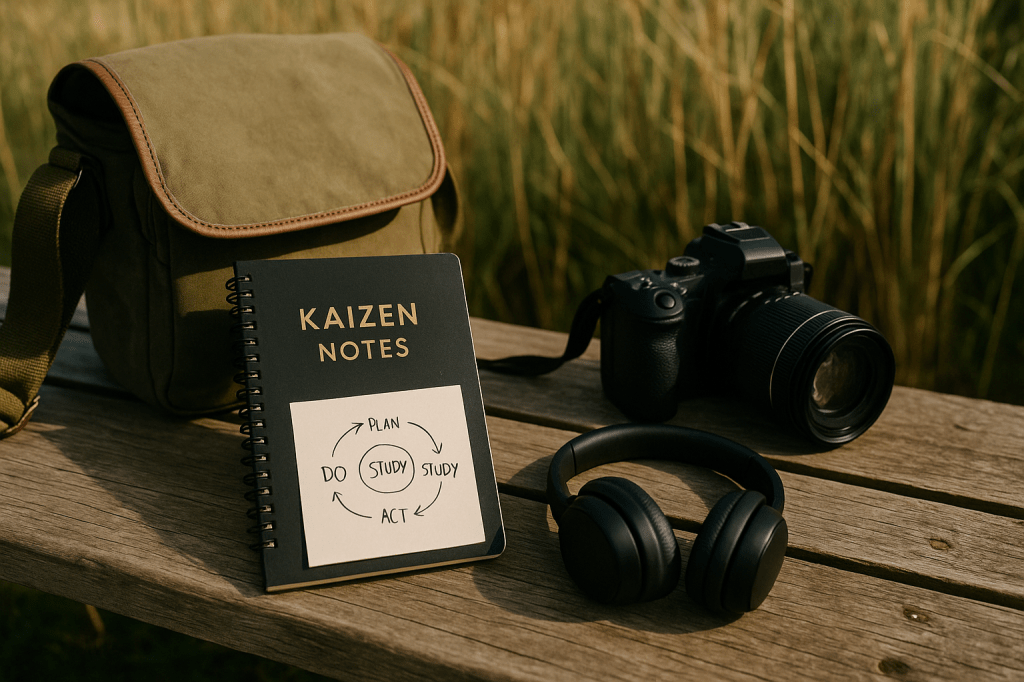

W. Edwards Deming (1900–1993) was an American statistician and management thinker who revolutionized modern industry. He argued that most business problems are caused by faulty systems, not lazy workers. His methods, like statistical quality control, the “Plan–Do–Study–Act” cycle, and his famous 14 Points, showed leaders how to build quality into processes, reduce waste, and continuously improve. Though largely ignored in the U.S. at first, Deming’s work helped Japan rebuild after WWII into a global manufacturing powerhouse. His legacy still underpins lean, Six Sigma, and nearly every serious approach to quality management today. (summary generated using AI)

Deming, through a series of seminars, taught me the Plan–Do–Study–Act (PDSA) cycle, a blueprint for never-ending improvement. He drilled into executives the idea that responsibility for quality rests with management, and that small, consistent changes compound over time.

That thinking led me to Kaizen.

Kaizen is a Japanese management philosophy meaning “continuous improvement.” It focuses on small, incremental changes at every level of an organization rather than sweeping overhauls. Rooted in postwar Japanese industry and influenced by thinkers like Deming, Kaizen emphasizes teamwork, employee involvement, standardization, and solving problems at the source. (summary generated using AI)

The two concepts fit together in a way that is almost poetic, and together, they helped save Japanese manufacturing after World War II.

In the ’90s, “Kaizen events” became a buzzword in American manufacturing. I participated in so many over the next 25 years that I lost count. If I had to guess, I’d say “a couple hundred” wouldn’t be far off.

Applying Kaizen to Life

At first, I applied Kaizen only to work. It didn’t occur to me that I could use the same methods to improve my personal life. That changed when I started applying it to creative work, especially writing and photography.

My approach was simple: I’d ask myself, What’s the smallest change I could make to improve my creative output? Then I’d run a Plan–Do–Study–Act cycle to test the idea. Some changes worked. Some didn’t. But that’s the point: I was always learning. And I still am.

Kaizen and Anxiety

Since retiring, I’ve been on a quiet mission to reduce my social anxiety without medication. I’ve made hundreds of small changes, and the results have surprised me.

Tonight, I’m going to an Angels game. In the past, the anxiety would’ve started days ago. I’d plan excuses to bail. I’d obsess over how to cope with the noise and crowds. Kaizen saved me.

Now, I carry earplugs in a small case on my keyring. I wear bone-conducting headphones that play brown noise to calm me. I meditate instead of medicate. And perhaps most surprisingly, I’ve learned to make eye contact, smile, nod, and say hello. That one simple gesture has reduced my old instinct to run and hide.

Rewiring My Social Behavior

I’ve applied Kaizen to social interactions too. I used to be awful at meeting people. I considered it a social disability for most of my adult life. My anxiety often made me appear rude or standoffish. I pushed people away rather than engage.

These days, thanks to many small changes, I greet people with an open, friendly smile. The improvement to my quality of life has been remarkable.

Just yesterday, I had four meaningful interactions with strangers. Those experiences prompted me to write this post.

What’s Next

I plan to write two follow-up posts:

- One will share stories of the interesting people I met yesterday while birding.

- The other will explore my incremental, AI-assisted writing process in more detail.

Both posts are directly connected to Deming and Kaizen. Both represent quality-of-life improvements. And that, in the end, is the whole point.

Also… I still think engineers are wizards. I married one. I call her my wizard princess.

Leave a reply to How I Actually Write: A Step-by-Step Breakdown – Peanuts In My Pocket Cancel reply